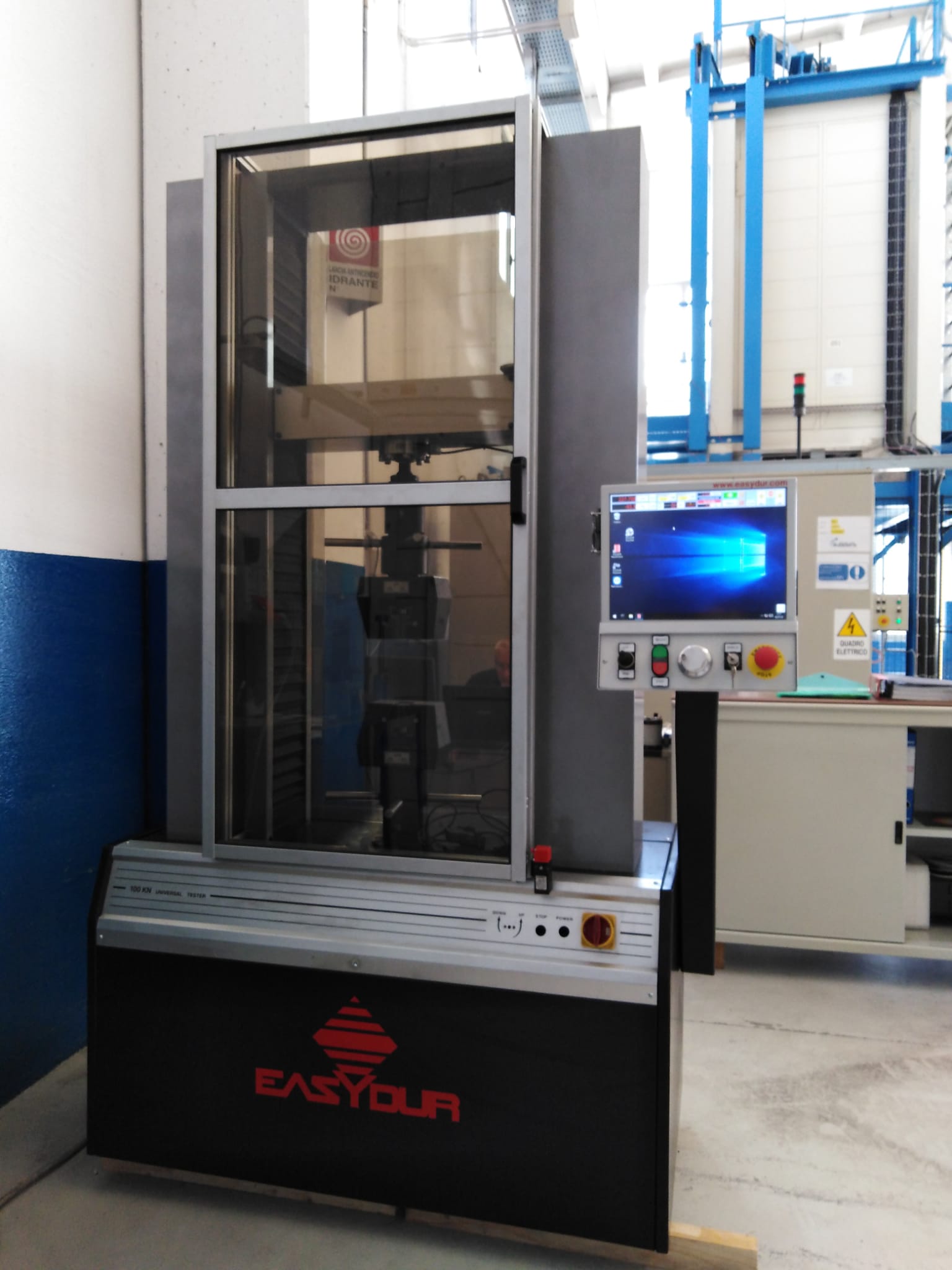

The MATEST H006, a new machine for tensile and compression testing with level 0.5 precision, is now part of LMA’s fleet.

Because we are aware that technological innovation starts from intuition and research, but we know that it then develops also through the various tests that anticipate the actual production.

Both following the Nadcap regulations on furnace management (for thermics treatments), and to be able to carry out new tests on some of our customers’ products, the new traction machine has come into operation, which will also be used to test new projects, already in the process of conception and development.

Its versatility is wide: it is not limited to working only with metal parts, but is also designed to stress test new production concepts in additive manufacturing.

Moreover, on request, it can also be used with compression method, instead of traction, for very specific technical assembly tests.

The MATEST H006 has a useful test height of 500mm (between clamps) and a useful height of 900mm (without clamps), for a useful test width of 590mm. From the advanced hardware configuration (without the use of mouse or keyboard), the new machine has a functional management and the dynamometer allows sinusoidal profile stress cycles, granting Matest remarkable performances.

LMA wanted to widen its range of action, both in the control and test phase, choosing the most suitable machine also to put even more strain on its creative capacity, design development and production.

Our projects of tomorrow will first be examined by a serious technological instrumentation, because even great ideas, to take flight, first need solid confirmations.

Once again, strong in the present and ready for the future!

Comments are closed.